Click the "blue word" above to follow us

In the production process of machining , machining quality is often the most concerned topic for factories. In order to improve the production pass rate, each factory has tried everything possible, but the quality risk caused by abnormal cutting tools still troubles many machining factories. Let's take a look at how the following customer solves the problem of abnormal cutting tools .

client needs

The customer is a well-known customer in the production of universal joints in the Yangtze River Delta region. During the production and processing process, there are often quality problems caused by abnormal tool (tool breakage, tool chipping) , and the customer uses reducing tool service life and increasing labor for this purpose. The way of inspection, but still treat the symptoms but not the root cause .

How to find Gillandin

In 2019 , Gillandin had done many projects for this client group, such as

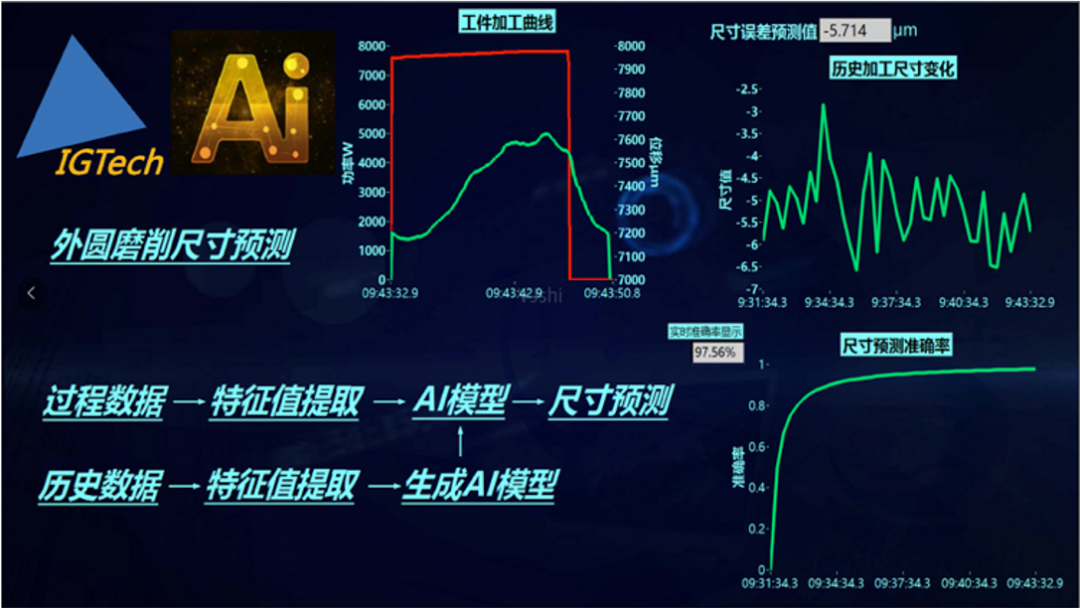

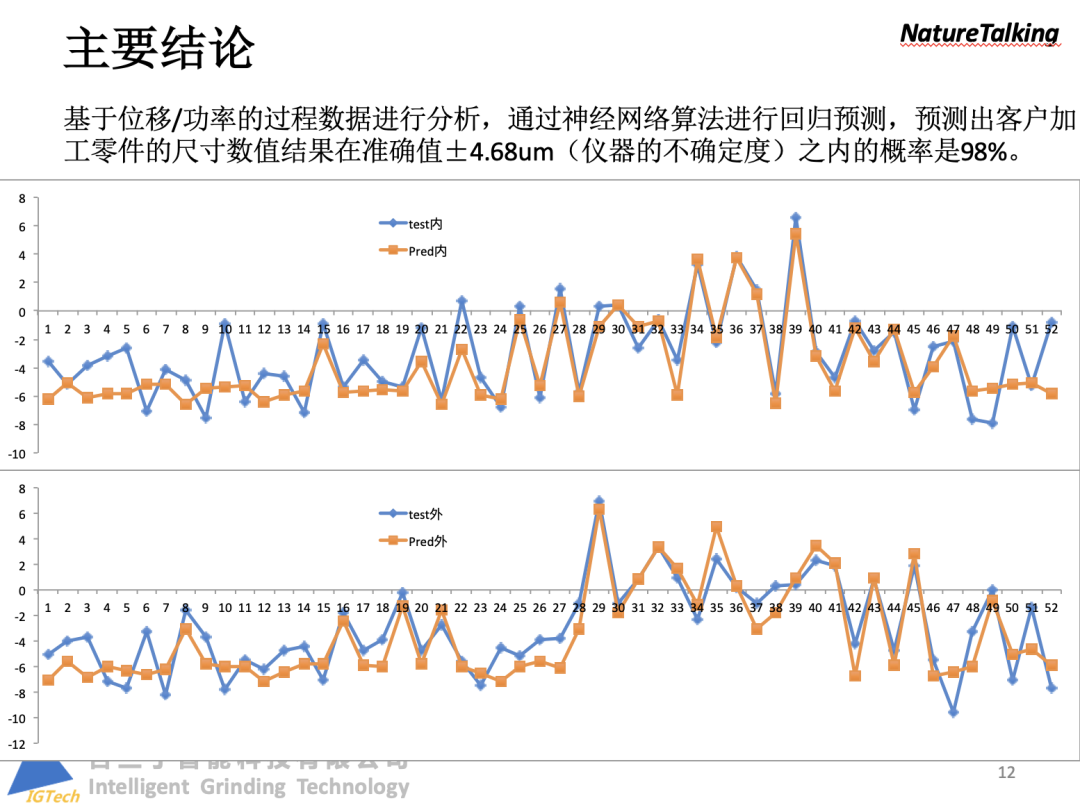

1. Ai quality prediction

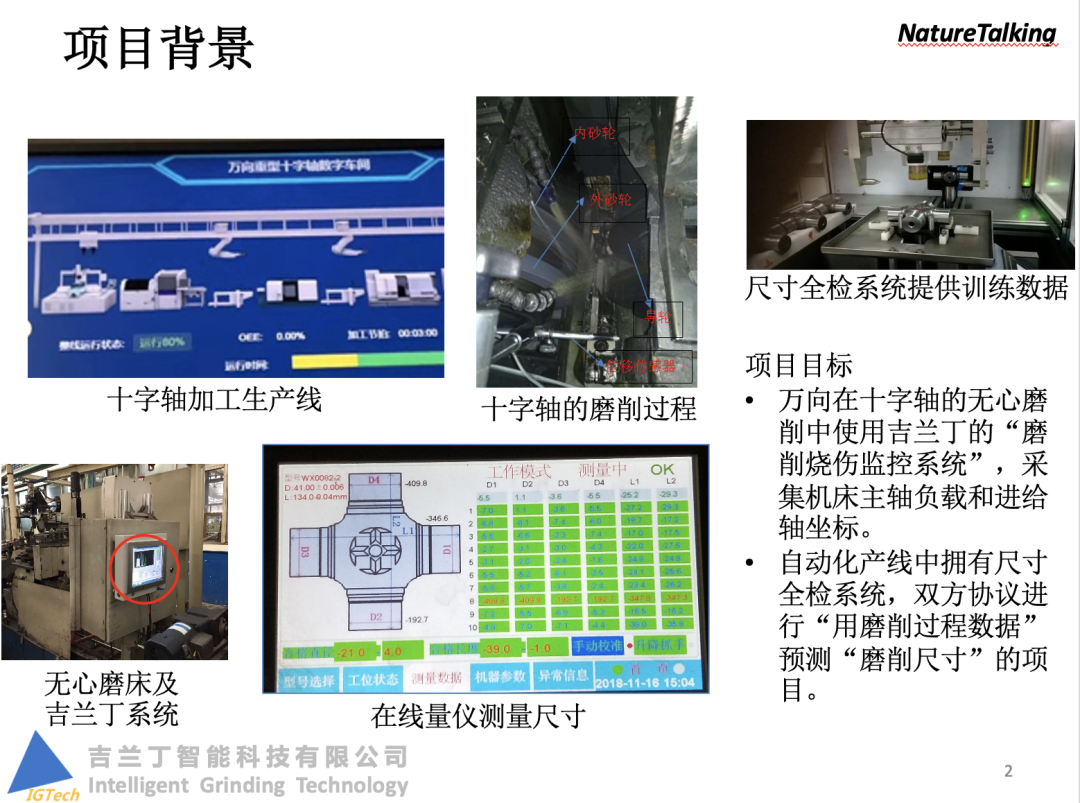

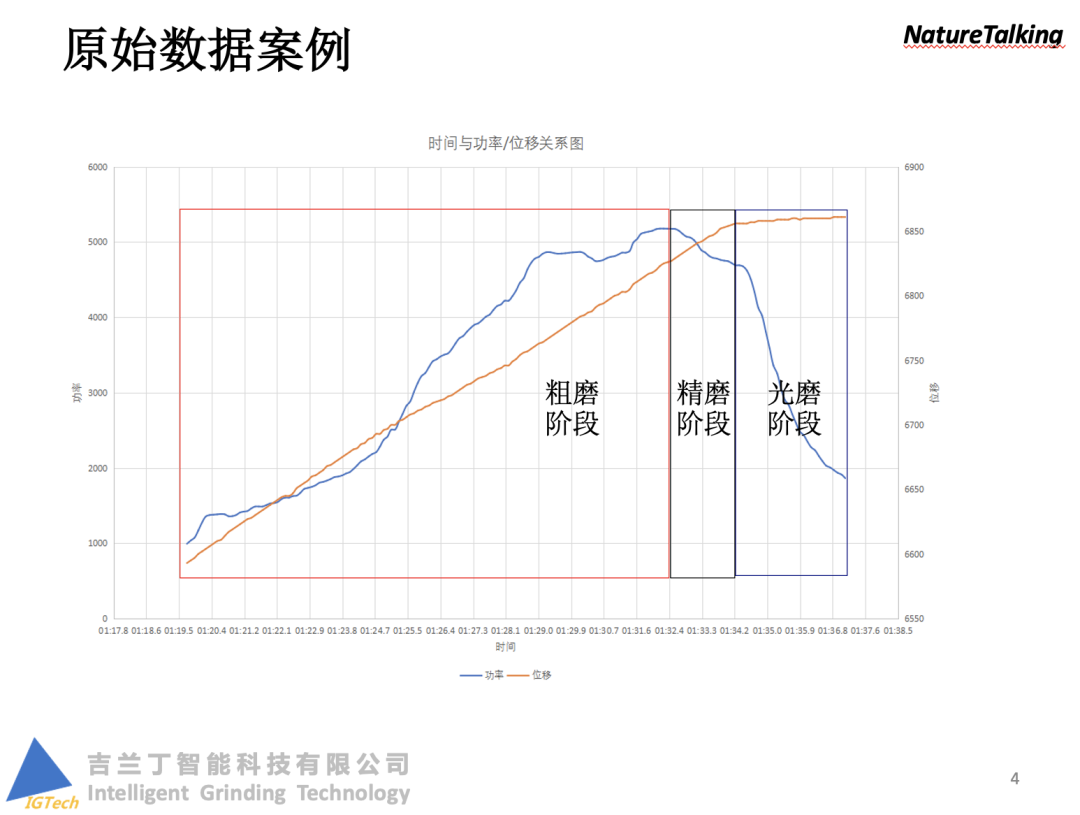

On the centerless grinding machine, the "grinding burn monitoring system" is used to collect the machine tool spindle load and the coordinates of the feed axis.

And based on the understanding of the grinding process, extract relevant eigenvalues + Ai algorithm application and quality inspection results combined with modeling

Finally , 98% model accuracy is obtained , which can replace the final quality inspection link after processing.

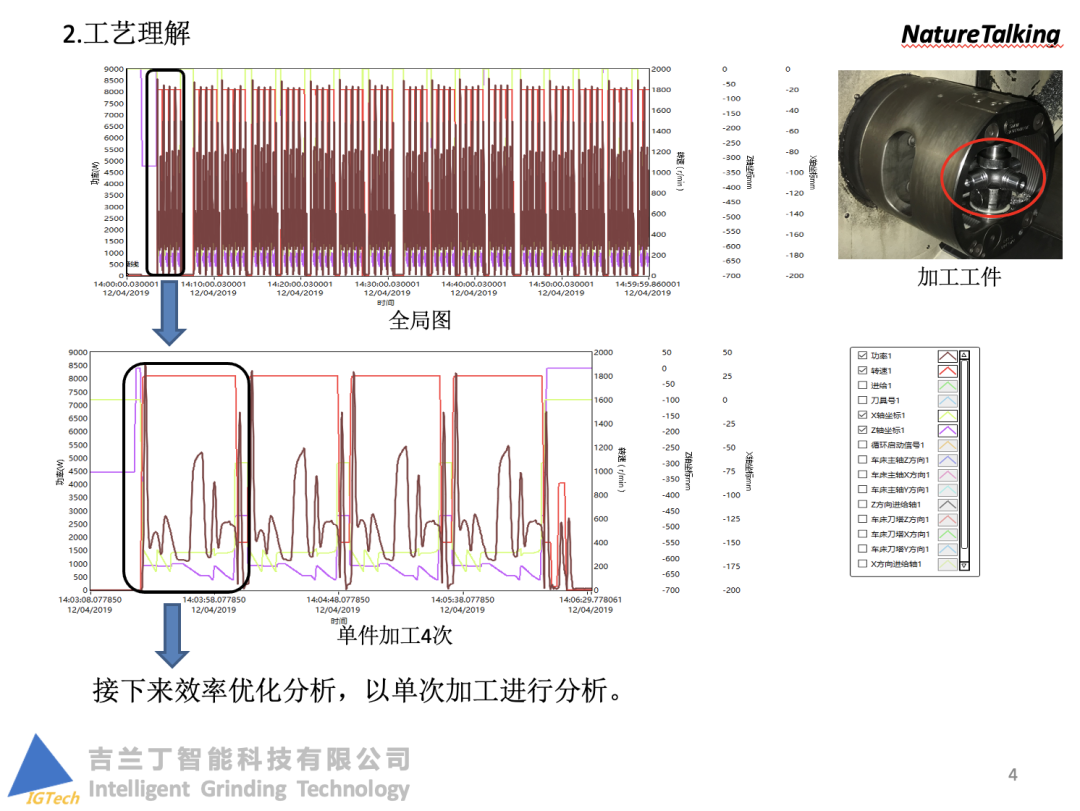

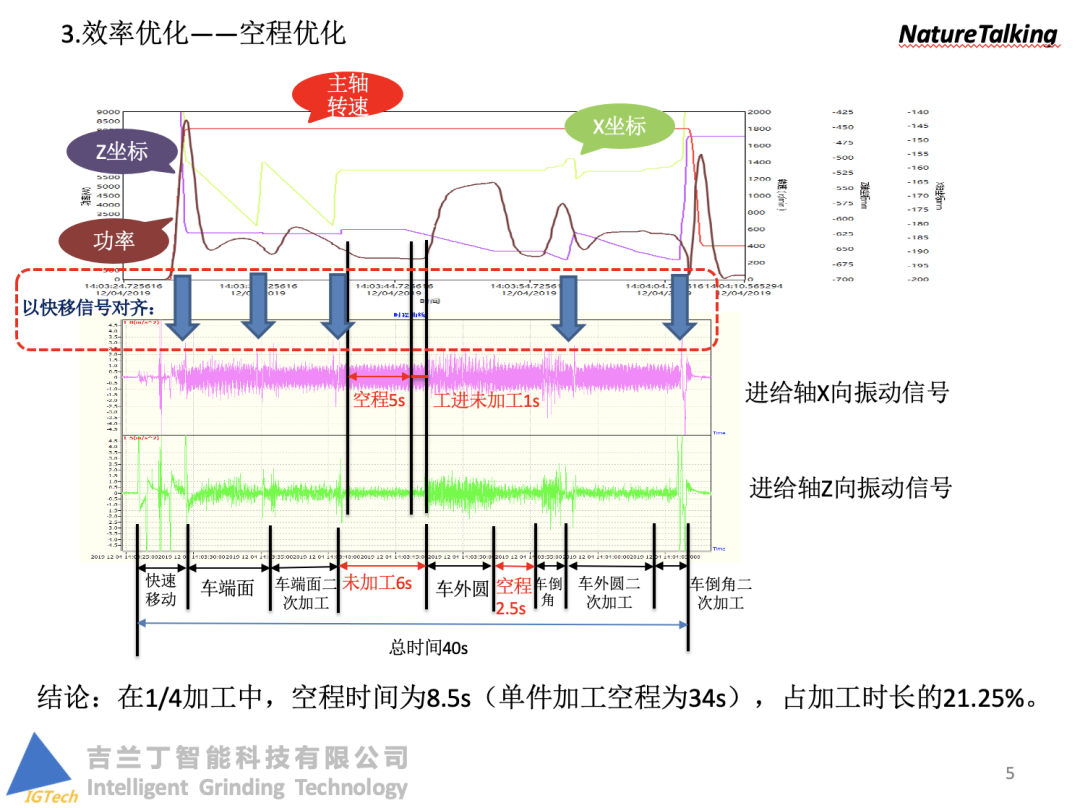

2. Processing technology optimization

By collecting the vibration of the machine tool and the action signal of the machine tool, the processing cycle is analyzed

In the end, it was found that there are many empty paths that can be optimized, which directly brings a 21% efficiency improvement point .

Therefore, the customer highly recognized Gillanding's technical ability and data analysis ability in the field of machining , so they came to us after the difficulties encountered this time.

Background of the project

Having said that, the background of the project faced this time is as follows:

Machine tool information

Machine Type: Siemens 828D

Machine type: single-turret 45° inclined horizontal lathe

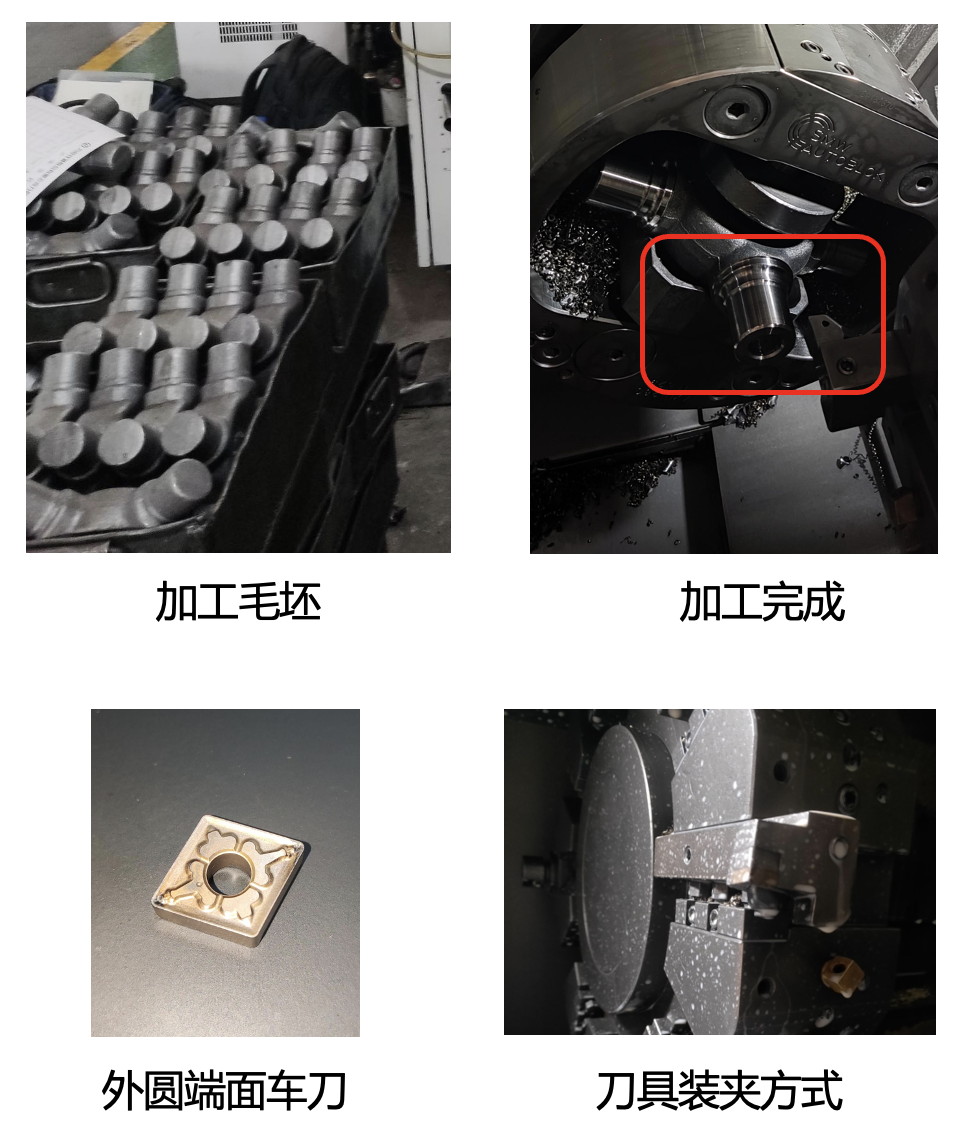

Monitoring tool: external cylindrical face turning tool

Processing material: cast steel

Monitoring signal: Spindle power, to achieve broken tool / chipping monitoring

Brief description of processing technology

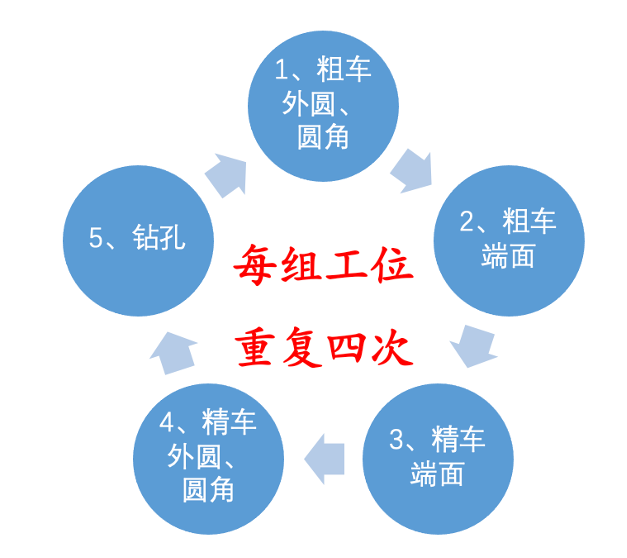

When processing the universal joint, the customer repeats the processing according to the following processing sequence.

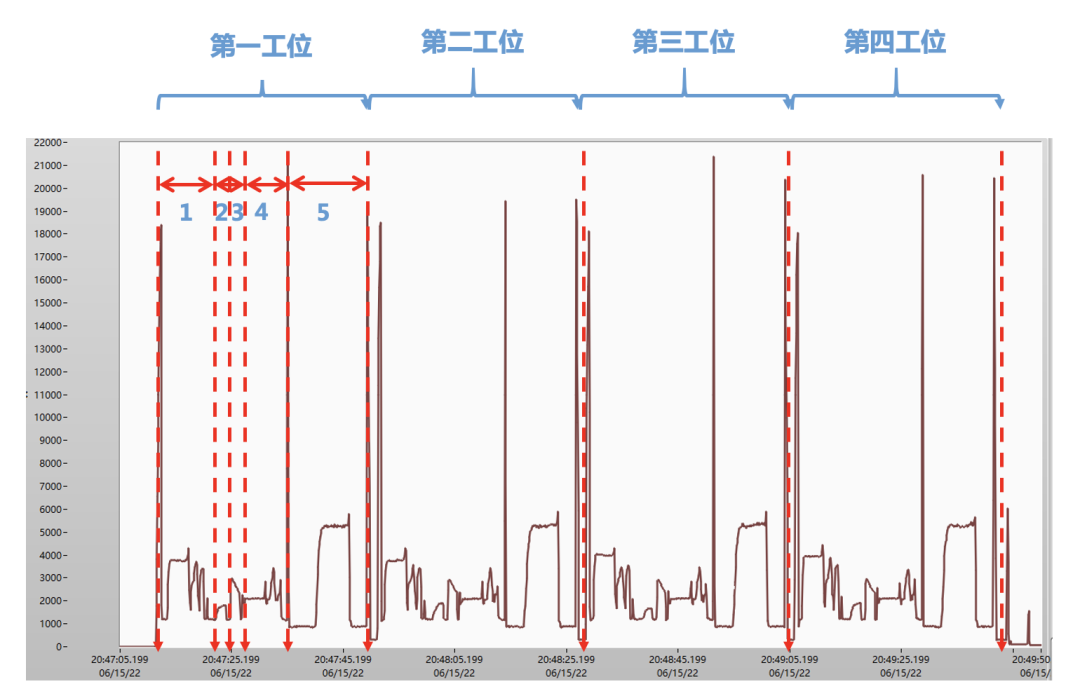

The corresponding processing signals are as follows

Processing principle explained

turning process

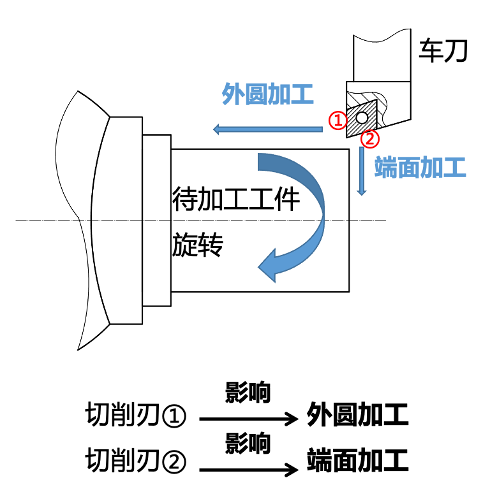

The spindle clamps the workpiece to be machined through the fixture and drives it to rotate at a high speed. At the same time, the turning tool performs relative movement along the radial or axial direction of the workpiece to be machined to complete the machining process.

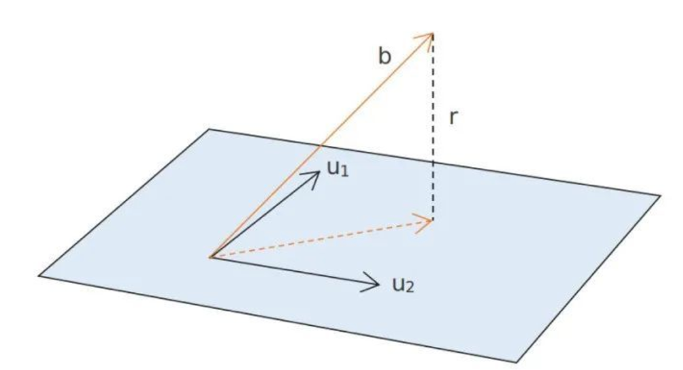

Vector decomposition

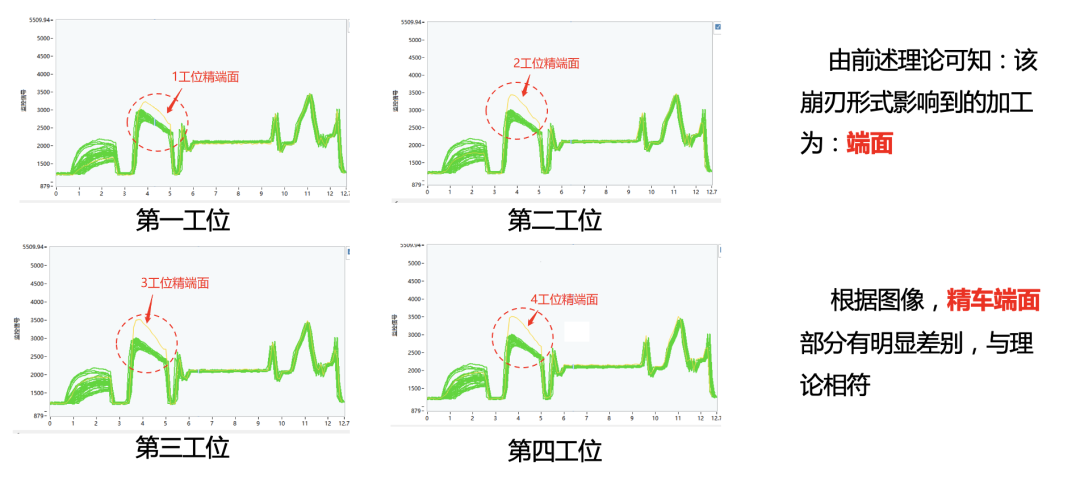

Based on the technological characteristics of the turning process, Gillanding decomposes and extracts the process data (power load data), and accurately monitors the machining process of the cutting edge that reflects the abnormality of the tool .

Ps: Gillandin's monitoring products are different from other manufacturers that implement tool monitoring with Ai algorithms at home, but more from the perspective of machining principles , deeply understand the microscopic process of machining, and add Ai algorithm through eigenvalue extraction. This is the competitive advantage of Gillandin products .

Monitoring effect

Through the previous deep understanding of the characteristics of the processing data, the premise is created for the accurate monitoring of this case.

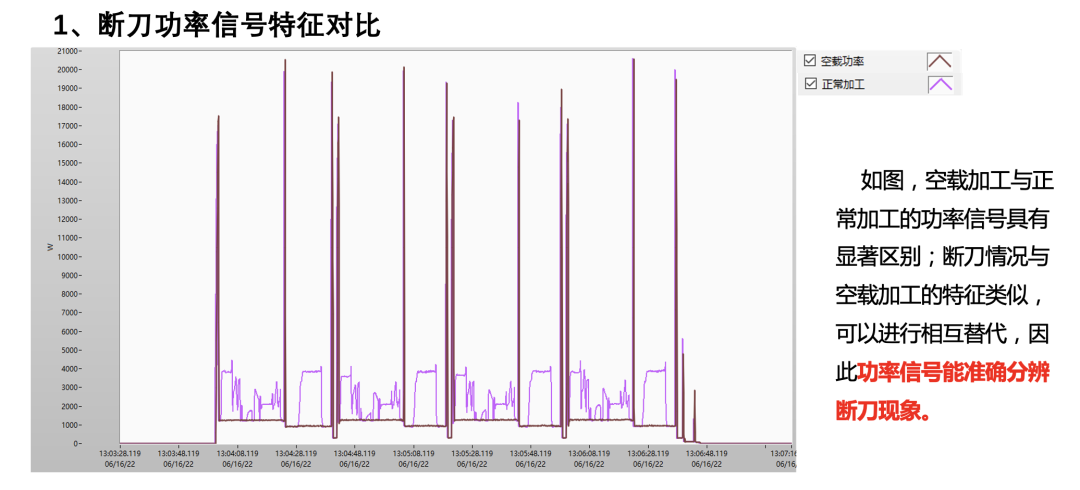

Broken knife (empty run monitoring)

Purple normal data Vs brown broken knife data

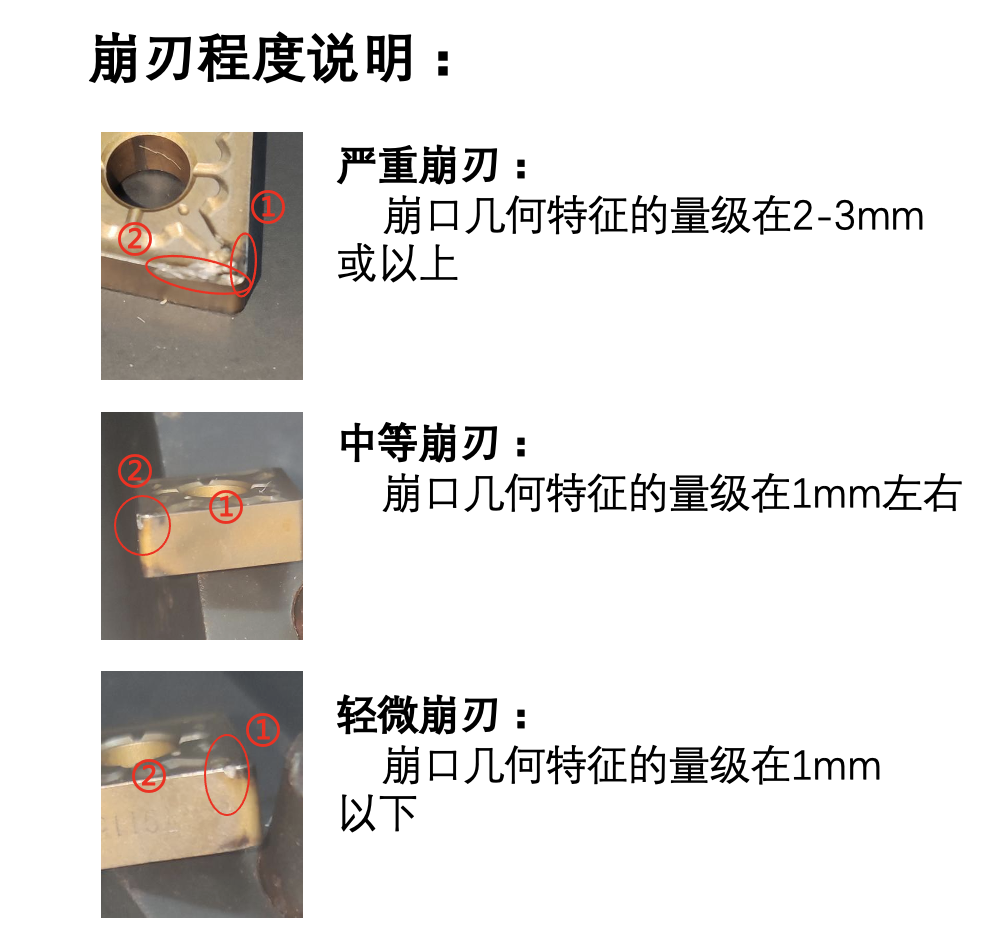

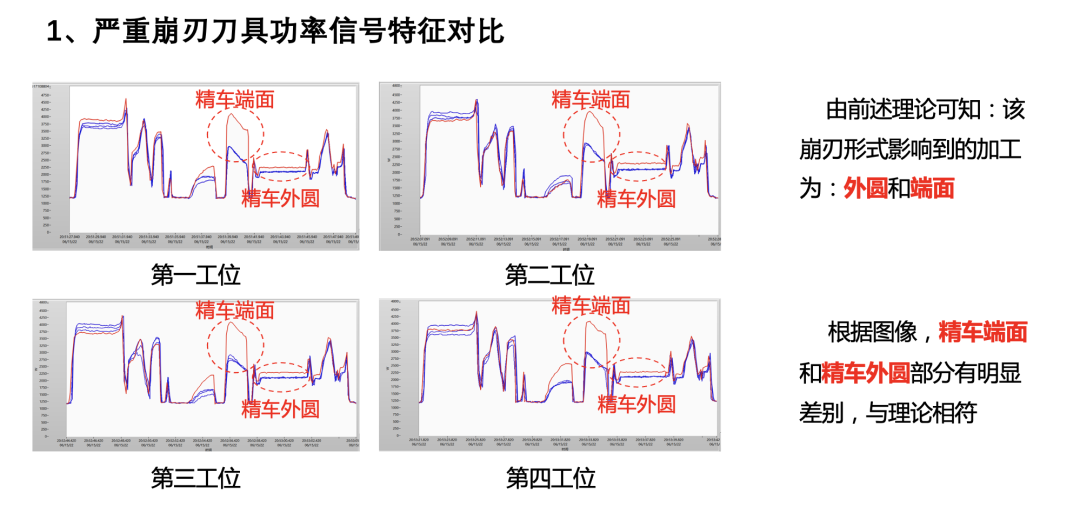

Severe chipping monitoring

Blue-purple normal data Vs red broken edge data

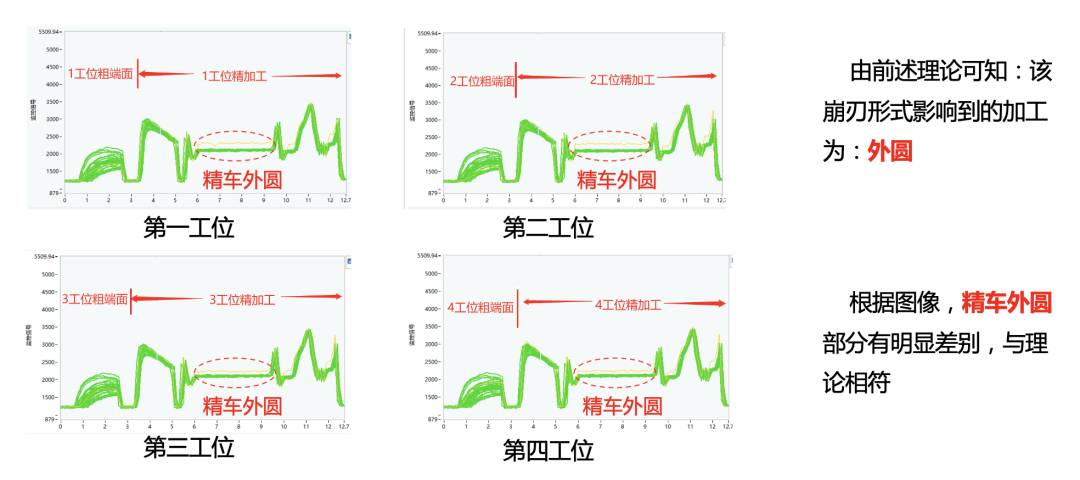

Medium chipping monitoring

Green normal data Vs yellow chipping data

Minor chipping monitoring

Green normal data Vs yellow chipping data

extra harvest

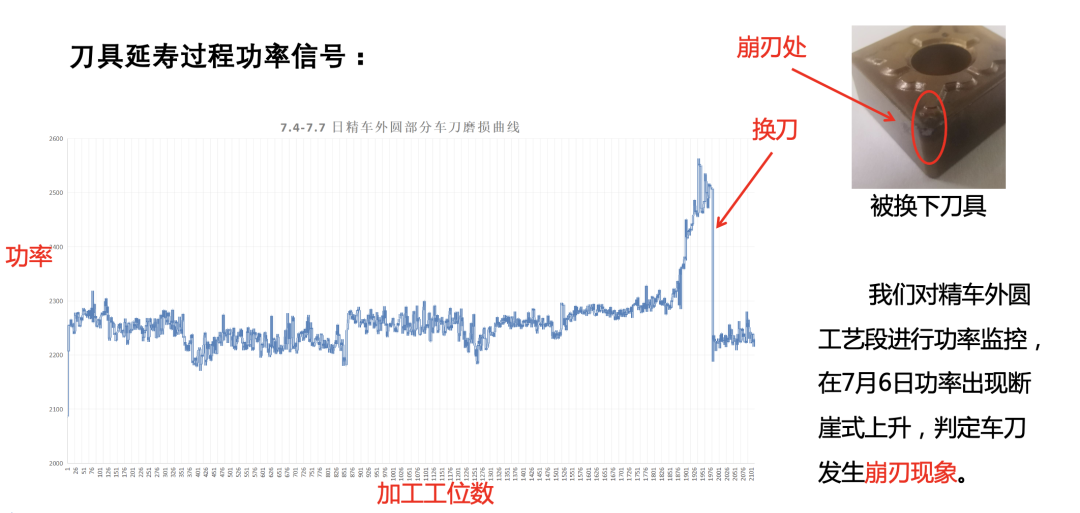

Through multiple days of data collection and analysis, in addition to realizing the customer's tool abnormality monitoring function, Gillanding also discovered additional value points for the customer's tool life extension .

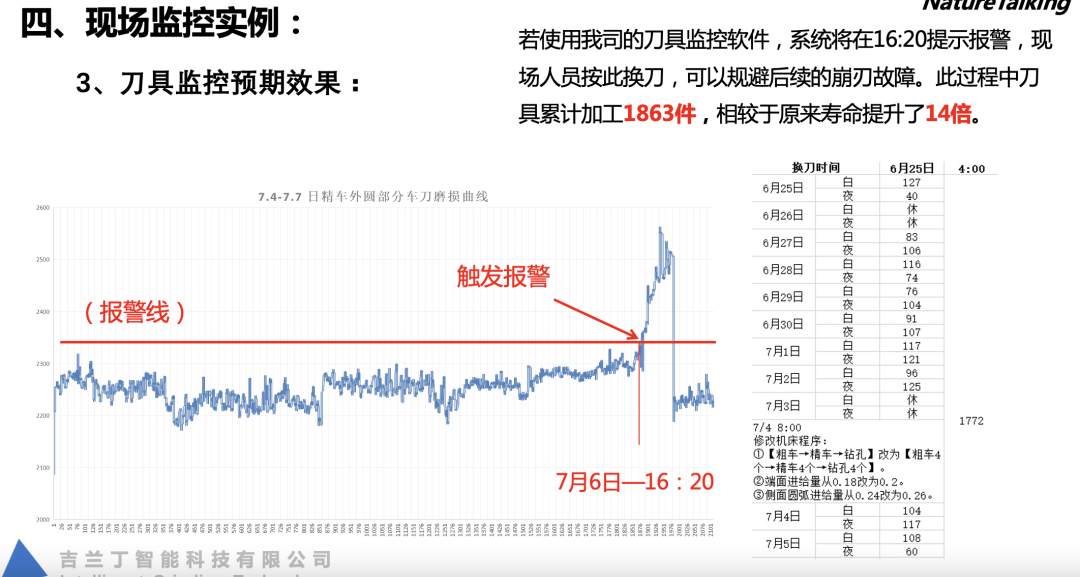

On-site personnel can change the tool according to this, which can avoid subsequent chipping failures. During this process, the tool has processed 1863 pieces in total, which is 14 times longer than the original life .

Customer benefits

Customers are using Gillandin's Tool Breakage Monitoring System and Tool Wear Monitoring System products to bring the following value.

Tool life extension

To help extend the life of the tool, the operator can change the tool according to the prompts of the software, so that the life of the tool can be maximized on the premise of ensuring the quality of the workpiece , up to 14 times , and the production cost can be saved.

Tool monitoring

Monitor the abnormal state of the tool. When the tool is slightly chipped or broken, the system will also accurately alarm, remind the operator to check the tool in time, and ensure the quality of the workpiece .

Recommended in the past

"Machine tool maintenance: see tricks and dismantling tricks? Planning for a rainy day? 》